Battery Performance & Safety (Thermal Runaway)

- Cell, module, and pack performance assessment

- Electrochemistry and aging under different cycling/temperature protocols

- Advanced modeling: P2D, ECM, kinetic and tabulated approaches

- Gas release, venting, and particle emissions during thermal runaway

- Failure propagation mechanisms and mitigation strategies

- Immersion cooling with e-fluids and innovative BTMS concepts

- Vehicle-level integration and safety evaluation

Introduction

This line addresses both the performance and the safety of lithium-ion batteries at cell, module, and pack levels. It integrates electrochemical performance evaluation, thermal management, and safety assessment with a particular emphasis on the thermal runaway phenomenon. Research combines advanced experimental characterization with numerical modeling and system integration to support safer and more efficient battery technologies for electric mobility and stationary applications.

Cell, module, and pack performance assessment

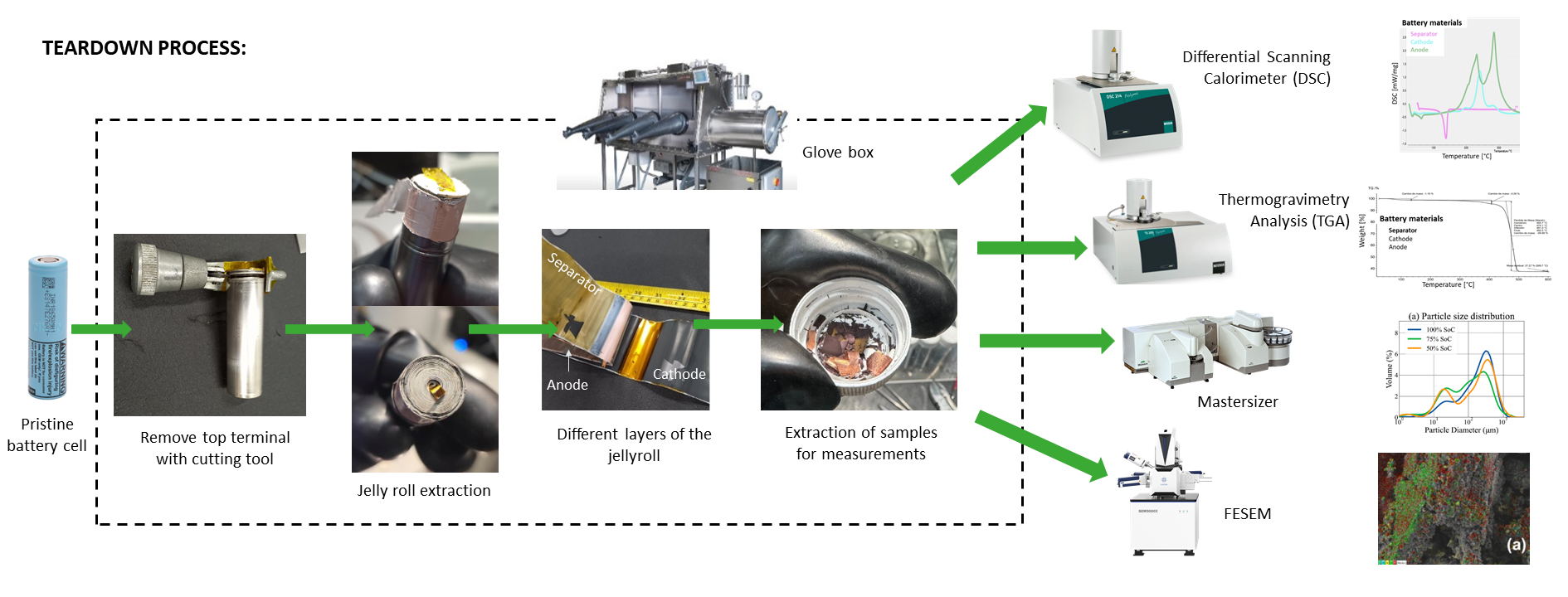

Teardown and material characterization workflow of cylindrical lithium-ion cells.

The process starts with the mechanical removal of the cell terminal and extraction of the jelly roll inside a glove box to ensure a controlled environment. The anode, cathode, and separator layers are separated and collected for subsequent analyses. Extracted samples are characterized using Differential Scanning Calorimetry (DSC) to evaluate thermal reactivity, Thermogravimetric Analysis (TGA) to assess material stability, Mastersizer measurements for particle size distribution, and Field Emission Scanning Electron Microscopy (FESEM) for morphological inspection and surface analysis.

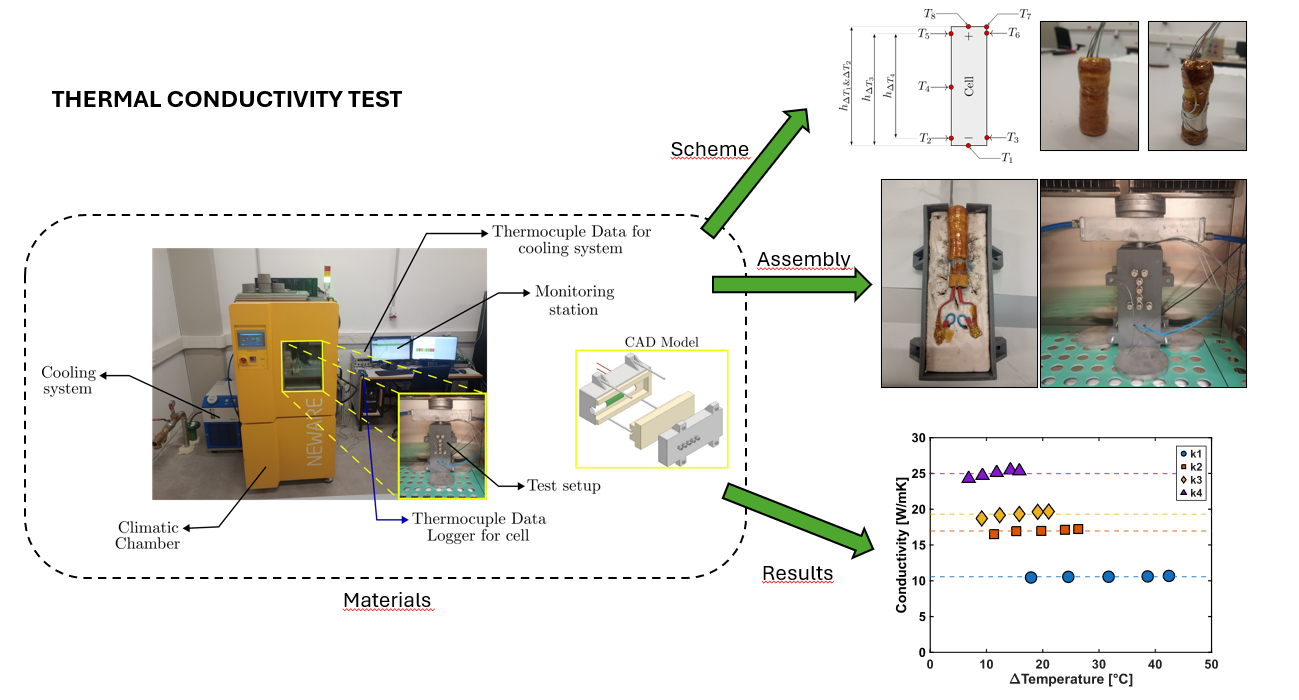

Experimental Setup and Results of the Thermal Conductivity Measurement for Battery Cells

Experimental Procedure and Analysis of Specific Heat Capacity in Battery Cell

Electrochemical performance and aging behavior of 18650 NMC cells under different cycling and temperature conditions.

Experimental setup showing the custom holder and thermocouple arrangement inside the ARBIN chamber.

Capacity retention versus cycle number at 25 °C and 50 °C under three cycling protocols (1C1D, 1C2D, 2C1D). Higher temperature and current rates accelerate degradation, particularly under 50 °C–2C1D conditions.

Nyquist plots obtained by electrochemical impedance spectroscopy (EIS) for pristine and aged cells after 200 and 500 cycles, evidencing increased charge-transfer resistance and SEI growth, especially at elevated temperature.

Average surface temperature evolution of the cell during cycling at 25 °C, highlighting self-heating effects at higher C-rates.

Advanced modeling: P2D, ECM, kinetic and tabulated approaches

Experimental and numerical workflow for the electro-thermal characterization of a 35 Ah semi-solid-state (Semi-SSBs) lithium-ion cell.

The experimental setup, including the compression system and the test cell.

Experimental and numerical workflow for the electro-thermal characterization of a 35 Ah semi-solid-state (Semi-SSBs) lithium-ion cell.

Test procedures — open-circuit voltage, hybrid pulse power characterization, and thermal tests — used to parameterize the electro-thermal model implemented in MATLAB/Simulink.

Experimental and numerical workflow for the electro-thermal characterization of a 35 Ah semi-solid-state (Semi-SSBs) lithium-ion cell.

Comparision of the simulated and experimental voltage and temperature profiles under different discharge rates, demonstrating good model agreement. The main objective and methodology are highlighted: experimental and numerical characterization under varying load and environmental conditions.

ARC Digital twin framework for modeling thermal runaway and venting gas combustion in a 21700 NMC cell under 100% SOC (Heat-Wait-Seek test) conditions. The workflow integrates multi-physics numerical models implemented in STAR-CCM+, combining 3D thermal runaway (TR) kinetics with 0D gas venting and gas-phase combustion submodels. The combustion mechanism, based on representative electrolyte vapors (CxHy, HF), is evaluated through laminar flame speed and ignition delay analyses, followed by identification of flame characteristics (non-premixed, high-velocity regime, mixing-controlled flame). The resulting flamelet-generated manifold is integrated into 3D CFD simulations to predict temperature, oxygen distribution, heat release rate, and overpressure within the cell environment, enabling a validated TR digital twin.

Gas release, venting, and particle emissions during thermal runaway

Cell structural characterization and internal morphology reconstruction after abuse using X-ray imaging and deep learning segmentation. Cell dimension analysis and venting cap evaluation through X-ray imaging, including jellyroll geometry, electrode and separator thickness measurements, venting valve area, and component identification.

Cell structural characterization and internal morphology reconstruction after abuse using X-ray imaging and deep learning segmentation. U-Net–based deep learning segmentation applied to overheated cells (HWS, 100% SOC) for 3D reconstruction of the internal morphology. The segmentation enables quantitative assessment of the remaining active materials (cathode, anode, and electrolyte regions) and comparison of material ratios under different abuse mechanisms (nail, laser, and hot-wire stimulation).

Visualization and analysis of gas–liquid venting and combustion dynamics in a cylindrical NMC811 cell (~4 Ah) using Schlieren and combustion image velocimetry techniques. (Top left) Schlieren images at different time instants (0–200 μs) during the early ejection event, showing vapor-phase structures and a darker liquid-phase core. (Middle left) Post-processed Schlieren images used to extract spray contours and liquid penetration. (Bottom left) Temporal evolution of spray penetration and penetration velocity, highlighting rapid jet expansion and subsequent deceleration. (Top right) Sequential frames (Δt = 50 μs) from high-speed imaging of flame particles during venting ignition. (Bottom right) Velocity vector field and streamline maps obtained via combustion image velocimetry, showing localized high-speed ejections and flow recirculation zones.

Morphological, compositional, and thermal characterization of NMC811 cylindrical cell materials (~4 Ah) at different states of charge (SoC). Morphology analysis including particle size distribution and SEM images of surface morphology for particles smaller than 100 μm and between 100–400 μm, revealing structural differences with SoC.

Morphological, compositional, and thermal characterization of NMC811 cylindrical cell materials (~4 Ah) at different states of charge (SoC). Elemental surface composition maps obtained via EDS for various SoC levels, and corresponding bulk composition profiles indicating changes in active material content and surface chemistry.

Morphological, compositional, and thermal characterization of NMC811 cylindrical cell materials (~4 Ah) at different states of charge (SoC). Thermal oxidation behavior evaluated by TGA and DSC tests for different SoC conditions, showing variations in mass loss and exothermic activity associated with electrolyte decomposition and cathode reactivity.

Failure propagation mechanisms and mitigation strategies

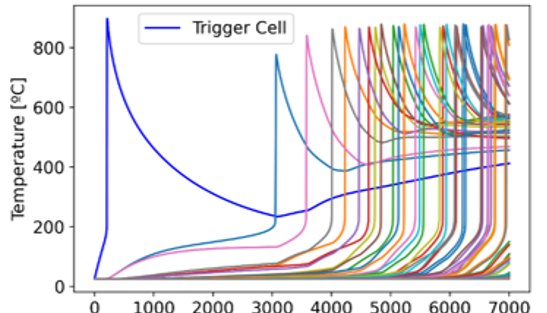

Evolution of vented gas propagation and temperature distribution in a 21700 NMC battery module during thermal runaway initiation.

The simulation corresponds to a 720-cell module where overheating of a single trigger cell initiates venting and subsequent gas dispersion. Time-resolved visualization of the venting process showing the expansion of gaseous products.

The simulation corresponds to a 720-cell module where overheating of a single trigger cell initiates venting and subsequent gas dispersion. Mass fraction evolution of vent gases, illustrating the progressive accumulation and transport within the module.

The simulation corresponds to a 720-cell module where overheating of a single trigger cell initiates venting and subsequent gas dispersion. Temperature fields revealing the thermal gradients generated during gas release and combustion, highlighting localized high-temperature zones exceeding 1000 °C near the trigger region.

Thermal runaway and flame front propagation in semi-solid electrolyte cells within an experimental three-cell mini-module configuration. (a) Experimental setup showing thermocouple positioning and containment structure for the triggered cell. (b–f) Sequential images illustrating the thermal runaway process and post-test condition of the module. The sequence captures the initiation of the runaway in the central cell, surface deformation, and propagation of the flame front through the semi-solid electrolyte, leading to partial rupture and localized charring of adjacent cells.

Immersion cooling with e-fluids and innovative BTMS concepts

Geometric model of the battery module with integrated cooling system.

Temperature distribution across the cell array during the propagation sequence obtained from CFD simulations.

Top-view temperature map showing localized propagation from the trigger cell to adjacent cells.

Temporal evolution of temperature for all cells, illustrating the characteristic exponential temperature rise and sequential triggering behavior typical of cascading thermal runaway.

Coupled vehicle–battery simulation framework and battery performance evaluation under driving conditions.

Schematic representation of the integrated vehicle model, which combines driver behavior, driving cycles, electric motor, transmission, brake controller, and auxiliary systems to evaluate the performance of the battery pack through longitudinal vehicle dynamics.

Comparison of simulated battery pack energy evolution with and without auxiliary loads against experimental data from Miri et al. (2020), showing good agreement across driving cycles.

Map of State of Health (SoH) as a function of thermal mass and cycle number, illustrating the impact of module configuration and thermal coupling on long-term degradation.