Control

- Powertrain control

- Monitoring and diagnosis

- Energy & thermal management

- Driving & fleet management

Introduction

The Control Team at CMT - Clean Mobility & Thermofluids focuses on the development of advanced methodologies for the control, optimization, monitoring, and management of propulsion systems and energy conversion processes. Its research activities cover a wide range of topics, including powertrain control, monitoring and diagnosis, energy and thermal management, as well as driving and fleet management. By combining physical modeling, optimization techniques, and data-driven approaches, the group aims to design innovative solutions that enhance performance, reduce environmental impact, and ensure the reliability of current and future mobility systems.

Powertrain control

Combustion control using in-cylinder pressure feedback

Read More→

Main Features

- Closed-loop dual-fuel control for RCCI and DDF modes

- In-cylinder pressure feedback for real-time combustion adjustment

- Control-oriented model coupling injection timing, fuel ratio, and IMEP

Control Strategy and Objectives

- Optimize combustion stability, efficiency, and emissions

- Adapt injection and fuel parameters across operating conditions

Close×

Sensor-based control for SCR-ASC aftertreatment systems

Read More→

Main Features

- Stochastic predictive control for hybrid energy management

- Data-driven estimation of power demand from past driving data

Control Strategy and Objectives

- Achieve near-optimal fuel economy without cycle preview

- Adaptively manage power split between engine and battery

- Ensure robust performance under varying traffic conditions

Close×

Knock detection via acoustic resonance modelling

Read More→

Main Features

- Sensor-based control of SCR + ASC systems

- Integration of NOx and NH3 sensors with adaptive feedback

- Real-time correction using cross-sensitivity factor (KCS)

Control Strategy and Objectives

- Optimize urea dosing for high NOx conversion and low NH3 slip

- Compensate sensor errors via adaptive KCS estimation

- Achieve robust and cost-effective emission control

Close×

Monitoring & Diagnosis

Knock detection via acoustic resonance modelling

Read More→

Main Methods

- Acoustic-based knock detection using resonance modelling

- Resonance indicators from HRR and pressure signals

- Analysis of resonance energy and auto-ignition behavior

Diagnostic Capabilities

- Classify knock intensity from mild to severe

- Distinguish normal combustion from knock in frequency domain

- Enable real-time, non-intrusive combustion monitoring

Close×

Data-driven combustion diagnosis using ANN and vibration signals

Read More→

Main Methods

- ML-based combustion diagnosis using knock sensor signals

- STFT and SVD for vibration signal processing

- ANN trained to predict key combustion metrics

Diagnostic Capabilities

- Estimate combustion phasing without pressure sensors

- Correlate vibration features with combustion anomalies

- Enable real-time, cost-effective combustion monitoring

Close×

Unsupervised knock classification with Time-Frequency analysis

Read More→

Main Methods

- Unsupervised knock detection using vibration analysis

- Time-frequency features extracted via STFT and SVD

- OC-SVM for combustion cycle classification

Diagnostic Capabilities

- Detect knock using low-cost vibration sensors

- Accurancy comparable to in-cylinder pressure methods

- Enable adaptive, sensorless knock intensity detection

Close×

Model-based diagnosis of SCR+ASC systems via sensor fusion

Read More→

Main Methods

- Model-based diagnosis of SCR+ASC using sensor fusion

- NOx and NH3 signals combined for emission estimation

- Luenberger-type observer detects injector and catalyst faults

Diagnostic Capabilities

- Identify injector failure and catalyst ageing in real driving

- Infer fault level from NH3 and NOx deviations

- Support adaptive control to ensure emission compliance

Close×

Energy & Thermal Management

Integrated energy-emission optimization for PHEVs using NLMPC-DP

Read More→

Main Features

- Hybrid NLMPC-DP control framework for PHEVs

- Real-time optimization of fuel use and NOx emissions

- Integrated powertrain and aftertreatment predictive control

Applications and Benefits

- Improve energy efficiency and emission compliance

- Dynamically balance power split between ICE and EM

- Demonstrate benefits in routes with zero-emission zones

Close×

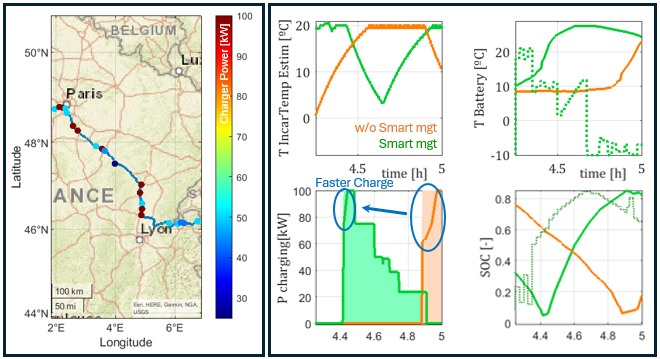

Predictive thermal management for battery electric vehicles

Read More→

Main Features

- Predictive thermal management for long EV trips

- Anticipatory control of battery and cabin temperature

- Unified framework for thermal and comfort control

Aplications and Benefits

- Reduce charging time via battery preconditioning

- Prevent derating and improve passenger comfort

Close×

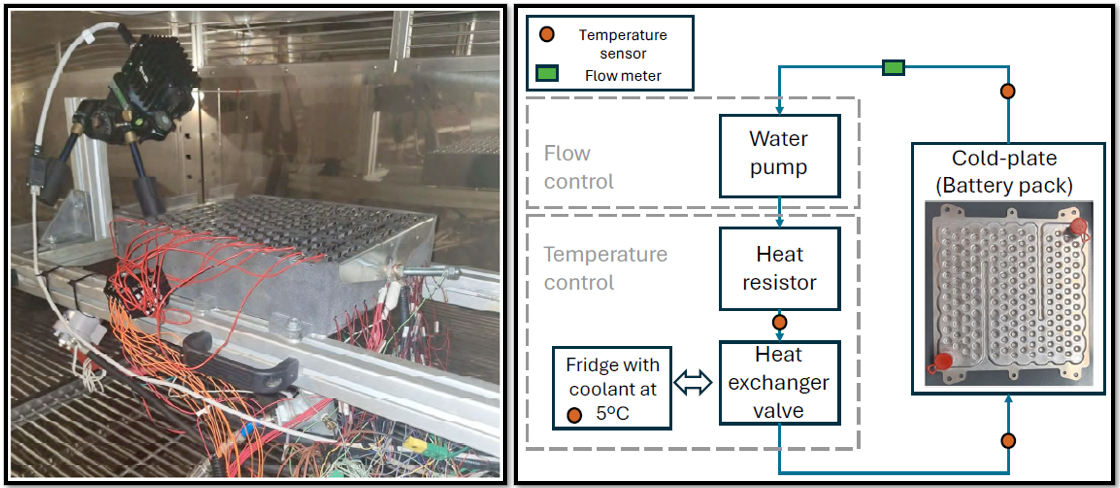

Dynamic optimization of battery thermal control for energy efficiency

Read More→

Main Features

- Physics-based model for BEV battery thermal control

- Experimental setup with active water-based cooling and heating

- DP optimization for energy-efficient temperature regulation

Aplications and Benefits

- Maintain battery temperature between 20-35 ºC

- Reduce thermal control energy in all climates

- Enhance system stability and battery lifetime

Close×

Driving & Fleet Management

Cooperative driving strategy using DP-MPC and V2X connectivity

Read More→

Main Features

- Cooperative control combining long-horizon DP and short-horizon MPC

- V2V and V2I connectivity to anticipate traffic and signals

- Real-time coordination of speed and lane changes

Aplications and Impact

- Reduce fleet fuel use and emissions without delaying travel

- Improve safety and traffic flow through cooperation

Close×

Context-aware speed optimization via DP and V2X communition

Read More→

Main Features

- DP-based optimal speed advisories using traffic and engine data

- V2X/LiDar integration to smooth driving and maintain safe gaps

Aplications and Impact

- Reduce fuel consumption and NOx emissions

- Enable smooth, robust eco-driving trajectories

- Basis for on-board eco-cruise and corridor control

Close×

City-wide MPC framework for real-time air quality control

Read More→

Main Features

- Real-time MPC with air-quality and QP optimization models

- Adjusts traffic density using urban data

- Enforces capacity limits and demand conservation

Aplications and Impact

- Mitigate PM10 hotspots and ensure regulatory compliance

- Scalable and computationally efficient for large cities

- Support sustainable mobility and environmental policies

Close×