Tribology

- E-fluids development and assessment for immersion cooling battery thermal management

- Predictive maintenance optimization applying AI

Introduction

We develop and assess e-fluids for immersion battery thermal management. Our capabilities include the characterization of formulations through thermal, electrical, and physicochemical analyses, focused on enhancing efficiency and performance in thermal management. In addition, we operate a dedicated area for predictive maintenance using AI, where machine learning techniques are applied to anticipate failures and improve efficiency in vehicles and industrial assets.

E-fluids development and assessment for immersion cooling battery thermal management

Physicochemical Characterization

Read More→

Evaluation of the main physicochemical properties of e-fluids provides essential information about their suitability for battery thermal management systems:

- Viscosity and Density - measured with Anton Paar SVM 3001 (ASTM D7042)

- Water Content - determined by Karl Fischer Coulometric titration (Metrohm 917) (ASTM D604)

- FT-IR Spectroscopy - performed with A2 Technologies iPAL

- ICP-AES - analyzed with Thermo Fischer iCAP 7400 RAD (ASTM D5185)

Close×

Thermal Properties Measurement

Read More→

Evaluation of thermal properties provides insight into the heat transfer efficiency and temperature stability of e-fluids:

- Thermal Conductivity and Heat Capacity - measured with the Thermtest THW-L1 system following ASTM D7896. Determined using the Transient Hot Wire (THW)

- These parameters are key to understanding how effectively an e-fluid dissipates heat, ensuring safe and efficient battery thermal management under variable operating conditions

Close×

Electrical Properties Measurement

Read More→

Evaluation of the electrical properties of e-fluids is essential to ensure dielectric safety, stability, and reliable performance in high-voltage battery cooling systems

- Resistivity and Dissipation Factor - analyzed with the DF9010 system (APT Power Technology Co.) following IEC 60247

- Electrical Conductivity - determined with the MBA MLA900 Conductivity Meter according to ASTM D2624

- Breakdown Voltage - measured with the Huazheng HZJQ-X1 Transformer Oil BDV Tester according to ASTM D1816

- These analysis support the development of safer and more efficient thermal management systems

Close×

Thermal and Electrical Aging Tests

Read More→

- The thermal and electrical aging tests evaluate the long-term stability and dielectric performance of e-fluids under simulated operational conditions. These in-house developed methods help study the effects of heat and electrical stress on the fluids, enabling the assessment of thermal oxidation, chemical stability, and dielectric degradation over time

Close×

Material Compatibility Testing

Read More→

The compatibility of e-fluids with plastics and elastomers is evaluated through immersion testing to determine their impact on material integrity and performance. After exposure, key properties are analyzed to quantify physical and mechanical changes:

- Mass variation - per ASTM D7216

- Hardness variation - per ASTM D2240

- Tensile strength and elongation - per ASTM D638

- Mass variation - measured according to ASTM D7216

Close×

Predictive maintenance optimization applying AI

Real-World Data Collection from Urban Buses

Read More→

- Ongoing collaboration with public transport operators to access real-world data from urban buses

- Integration of onboard sensor data (temperature, pressure, flow, diagnostics) to train and validate predictive maintenance models

- Access to multi-source datasets under real operating conditions enables robust and context-aware machine learning models

- Supports the deployment of AI-driven systems in industrial environments, ensuring relevance, explainability, and operational impact

Close×

Building Machine Learning Solutions from Field Data

Read More→

- Real-world sensor data enables understanding of system behaviour under operational conditions

- Clean, structured, and labeled datasets are key to model accuracy and generalizability

- Large historical datasets allow training of Machine Learning models for tasks such as classification (e.g., Random Forest, XGBoost, LightGBM)

- The use of real data helps bridge the gap between theoretical models and practical deployment

Close×

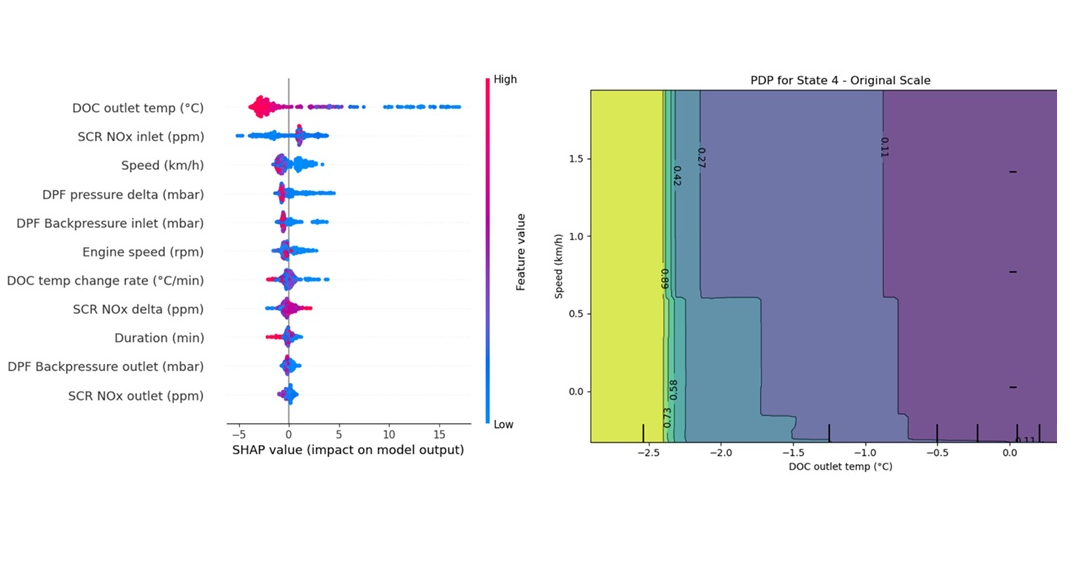

Explainable AI for Maintenance Decisions

Read More→

- Developing ML models is not enough; understanding their decisions is critical for industrial adoption

- Tools like SHAP (Shapley Additive Explanations) and PDP (Partial Dependence Plots) reveal how input variables influence model predictions

- Explainability ensures transparency and trust, enabling engineers and decision-makers to validate and act on AI outputs

- Interpretable models foster collaboration between data scientists and domain experts, driving actionable insights in maintenance contexts

Close×